Circuit module protection design: Practical guidelines and technical analysis

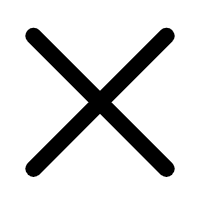

Protection circuit module definition

A protective circuit module is a device or circuit component used to protect a circuit from adverse conditions such as voltage surge, current overload, and overheating. They are commonly used in power systems, communications equipment, computer hardware, and other electronic devices to ensure the safety and reliability of these devices under a variety of operating conditions. Protection circuit modules may include functions such as overvoltage protection, overcurrent protection, and overtemperature protection to protect critical components and electronic components by monitoring and responding to adverse conditions in the circuit. These modules can also be designed with additional features such as short-circuit protection, temperature protection, electrostatic discharge protection, and power management.

The constitution and principle of protection circuit module

The components of the basic protection circuit module will have MOSFETs and integrated circuits (ics). A MOSFET is a control switch. When a specified threshold is reached, it will turn off the voltage during charging. It will also shut down the discharge of the battery pack when it discharges too quickly or when the discharge level is too low during long-term storage. The overcharge and overdischarge thresholds are measured by the IC, which will provide output instructions to the MOSFET.

The IC in the protection circuit module will be designed to measure the voltage of each cell. It will be programmed to turn off the MOSFETs to prevent the battery from overdischarging or overcharging. The control switch measures the voltage at both ends of the battery terminal. Therefore, it is common to place two MOSFETs in the design. One MOSFET is used for overcharge protection and the other MOSFET is used for overdischarge protection.

During normal operation, both MOSFETs will be on. If the battery experiences too high a voltage during charging, the IC switches the MOSFETs used for charge protection to the "off" position to turn off the voltage at the terminal. However, as long as the MOSFETs used for overdischarge protection are still in the "on-on" state, the battery will still be able to discharge through both MOSFETs.

The same method is also applicable to the process of overdischarge protection. If the IC detects that the battery is discharging too fast or at too low a state, it sets the MOSFETs used for overdischarge protection to the "off" position to prevent further battery discharge. However, as long as the MOSFETs used for overcharge protection are still on, the battery pack is still able to charge the battery through both MOSFETs.

The working principle of a protection circuit module depends on the specific components and design functions it contains. Here's how some common components work:

Overvoltage protector: An overvoltage protector usually consists of a diode that will turn on when the input voltage exceeds a set threshold, directing the overvoltage to ground or another safe path, thereby protecting other components in the circuit from damage.

Overcurrent protector: Overcurrent protector usually uses a resistor or current sensor to detect when the current exceeds a preset threshold, and triggers a protective action through a feedback signal, which may be to cut off the circuit, adjust the current or limit the current.

Overtemperature protectors: Overtemperature protectors usually detect temperature changes in the circuit through a temperature sensor or thermistor and trigger protective actions, such as cutting off the circuit or reducing power, once the temperature exceeds a set threshold.

Voltage regulator: The voltage regulator adjusts the output voltage according to the change of the input voltage to ensure that the output voltage is stable within the preset range. This may be achieved through feedback control loops, such as using a regulator or switching regulator.

Overload protector: An overload protector usually triggers a protective action by detecting a change in current in the circuit, and once an overload condition is detected, it may cut the circuit or take other measures to limit the current.

Protective relays: Protective relays are usually composed of electromagnetic relays. When bad conditions are detected, the circuit is cut off or switched by controlling the trigger of the electromagnetic relay.

Fuse: The working principle of the fuse is that when the current exceeds the rated current of the fuse, the conductor inside the fuse melts or breaks, thereby cutting off the circuit to protect other components from overload damage.

The working principle of these components may vary depending on the specific design and application, but their basic goal is to detect adverse conditions in the circuit and take appropriate measures to protect other components in the circuit.

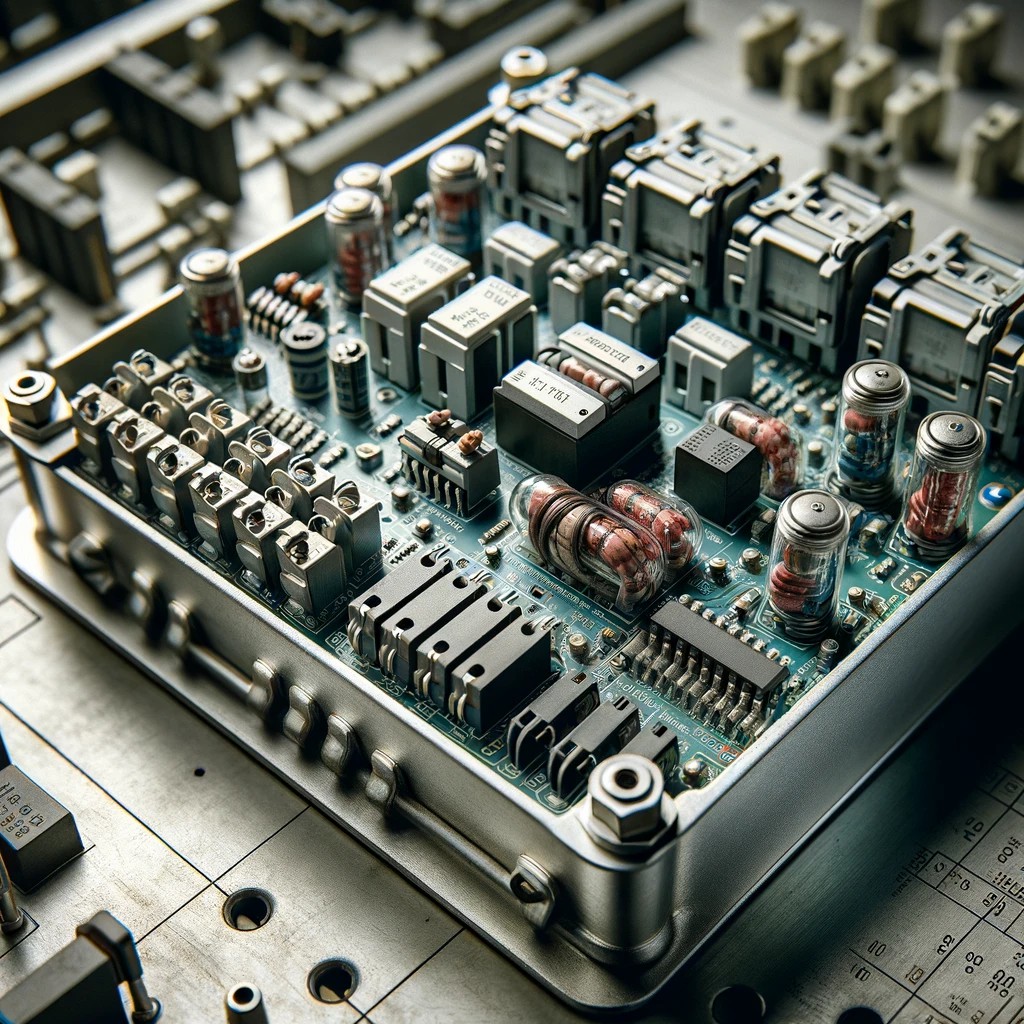

Protection circuit module design - embedded charger and embedded battery pack

Embedded battery pack and embedded charger in protection circuit module design usually refers to the integration of battery pack and charger into a circuit board or module to achieve the protection and charge management functions of the battery pack.

Embedded battery pack: This means that the battery pack is integrated directly into the board or module, rather than as an external component. The design of the embedded battery pack needs to consider factors such as the type of cell, capacity, charge and discharge characteristics, and safety, and ensure good integration and interaction with the rest of the system.

Embedded charger: This means that the charger circuit is integrated into the same circuit board or module to manage the charging process of the battery pack. Embedded chargers usually include components such as a charge management chip, a charge control circuit and an input power management circuit to ensure safe and efficient charging of the battery, and to prevent overcharge, overdischarge and other problems.

Integrating protection circuit modules, battery packs and chargers simplifies system design and improves system integration and performance, while also providing more reliable and safe battery management and charging functions. This design is commonly seen in portable electronic devices, embedded systems, mobile robots and other applications.

Protection circuit module design is critical in many applications

Power system: In the power system, the protection circuit module can be used to prevent overload, overvoltage, undervoltage and short circuit problems. This is essential to protect equipment from voltage surges or unstable power supplies.

Communication equipment: In communication equipment, the protection circuit module is used to protect the circuit from problems such as electrostatic discharge, electromagnetic interference, and overcurrent. This helps ensure the reliability and stability of communication equipment.

Industrial control systems: In industrial control systems, protection circuit modules can be used to prevent equipment from being affected by overload, short circuit and other abnormal conditions, thus ensuring the continuity and safety of the production process.

Automotive electronic systems: In automotive electronic systems, protection circuit modules can be used to protect electric drive systems, engine control systems, and other critical systems from electrical failures and external disturbances.

Household appliances: In household appliances, protective circuit modules are used to ensure the safe and reliable operation of equipment and to prevent fire or other dangerous situations caused by electrical failures.

Medical equipment: In medical equipment, protective circuit modules can be used to protect equipment from electrical interference and other electrical problems, ensuring the stability and safety of medical equipment.

Protective circuit module design plays an important role in almost all electronic devices and systems to ensure that equipment is protected from electrical failures and external interference, improving the reliability and safety of equipment.

Protection circuit module design has many advantages and broad prospects

Safety enhancement: The protection circuit module design can effectively protect electronic equipment from adverse conditions such as overvoltage, overcurrent, and overtemperature, improving the safety and reliability of equipment.

Extend equipment life: By detecting and responding to adverse conditions in a timely manner, the protection circuit module design can reduce equipment damage and failure and extend the service life of the equipment.

Saving maintenance costs: Reducing equipment failure and damage can reduce maintenance and replacement costs, saving maintenance human and material resources.

Improve the user experience: The stability and reliability of the equipment can improve user satisfaction and trust, and promote the promotion of brand image.

Wide adaptability: The protection circuit module design can be widely used in a variety of electronic equipment and systems, including power systems, communication equipment, industrial control systems, automotive electronics and other fields.

Technological innovation: With the development and innovation of electronic equipment technology, the design of protection circuit modules is also constantly evolving and improving to provide more advanced protection functions and performance for new equipment.

Environment-friendly: By improving the stability and reliability of the equipment, it reduces the waste of resources and environmental pollution caused by equipment failures.

Sum up

In the future, with the popularization of electronic equipment and the expansion of application range, protection circuit module design will continue to play an important role. With the further development of intelligent, Internet of things, electrification and other trends, the stability, safety and reliability of electronic equipment will be increasingly high requirements, protection circuit module design will play an important role in this process, and continue to expand the application field and improve the technical level.